| Product specifications | |

| Size | 200A ~ 1,000A . Adjustable filter mesh specifications to suit on-site needs . Separate consultation required for 1,100A or more |

|---|---|

| Product Use | Various water and sewage facilities requiring filtration |

| Material | Body & Gate : GCD450, SSC13, SSC16 |

| Product Features |

|

| Product Certification |

|

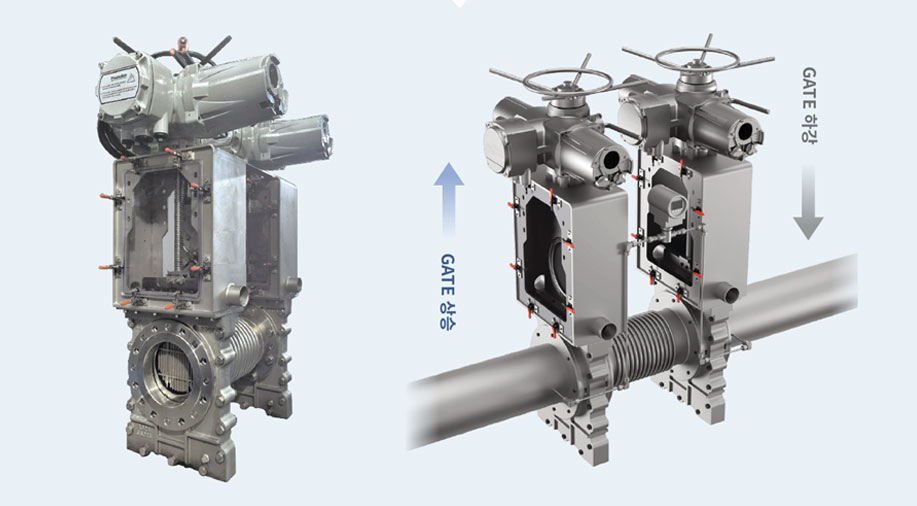

| Fitting Method | Flange |

| Drive unit | Electric |

| Patent |

|

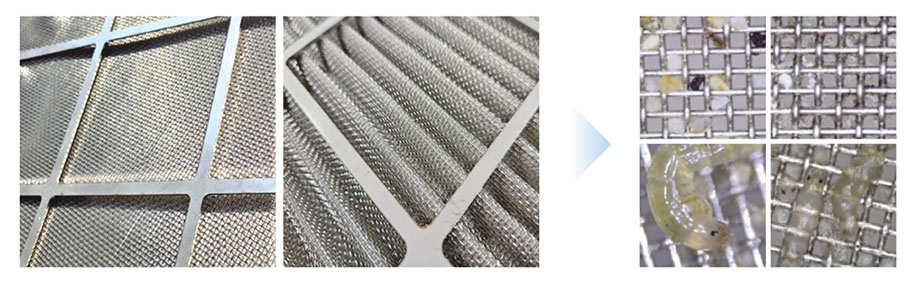

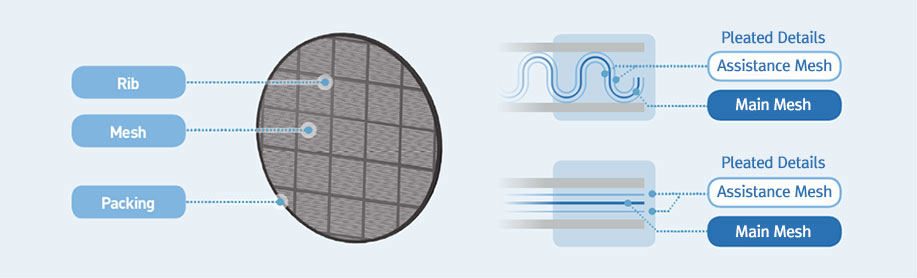

Rib |

by sludge in the fluid. |

|---|---|

| Main Mesh |

|

| Assistance Mesh |

|

|---|---|

| Packing |

|